Views: 0 Author: Site Editor Publish Time: 2025-09-04 Origin: Site

A self-drilling screw is an essential fastener used in a variety of applications where speed, efficiency, and precision are paramount. Known for its ability to drill its own pilot hole while being driven into materials, the self-drilling screw eliminates the need for a pre-drilled hole, making it an ideal choice for professionals and DIY enthusiasts alike.

This screw type is commonly used in metal, wood, plastics, and even masonry applications. With its drill-shaped point, it can penetrate tough materials, saving time and effort compared to traditional screws that require a separate pilot hole. In this article, we will explore everything you need to know about self-drilling screws, their types, uses, advantages, and best practices for installation.

A self-drilling screw is designed with a drill-shaped point, which allows it to drill and tap its own hole in materials such as metal, wood, and plastic. The screw itself performs two essential tasks: drilling the hole and securing the material, all in one step. This feature eliminates the need for a pre-drilled hole, making self-drilling screws an essential tool in the fastener industry.

Self-drilling screws are equipped with a pointed tip that resembles a drill bit. This design enables the screw to penetrate the material and create its own hole as it is driven in. The tip can vary in size and shape, depending on the application, but it is always sharp enough to efficiently drill through various substrates. As the screw enters the material, it not only drills the hole but also taps into the material, forming threads that ensure a secure fit.

Unlike other types of screws, self-drilling screws do not require a separate pilot hole, which makes them faster and more convenient to use, especially in industrial settings.

There are several types of self-drilling screws, each designed for specific materials and applications. Here are some of the most common types:

Pan Head Self-Drilling Screws

The self drilling screw pan head is one of the most common types. These screws feature a slightly rounded, flat head that sits above the surface of the material. The pan head provides a broad surface for better load distribution, making it ideal for softer materials or when a smooth, flush finish is not required.

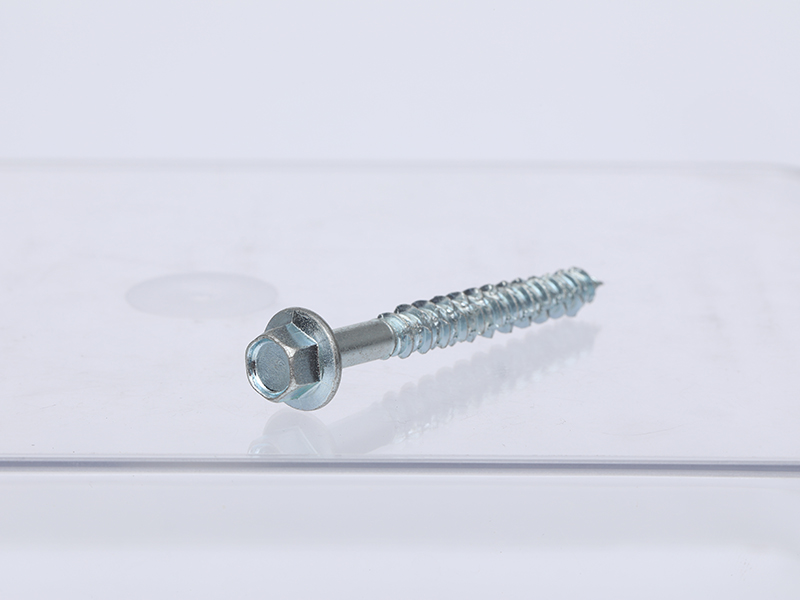

Hex Washer Head Self-Drilling Screws

The self drilling screw hex washer head features a hexagonal head with an integrated washer. This design ensures a tighter grip and better sealing, especially when used in metal roofing and siding applications. The washer helps distribute the pressure, preventing damage to the surface and improving the screw’s holding power.

Flat Head Self-Drilling Screws

These screws have a flat head that sits flush with the surface of the material. They are commonly used when a smooth finish is necessary, such as in drywall or thin sheet metal. The flat head minimizes the risk of protruding edges that could be dangerous or unsightly.

Truss Head Self-Drilling Screws

The truss head screw has a wide, low-profile head that helps distribute the load evenly. This type of screw is often used in applications where thin materials or soft surfaces are involved, as it reduces the risk of crushing.

Choosing the right self-drilling screw depends on several factors:

Material Compatibility: The material you are working with will dictate the type of screw you need. For example, steel may require a more robust screw compared to wood or plastic.

Head Style: Depending on the desired finish and application, you may need a pan head, hex washer head, or flat head screw. Consider the appearance and strength requirements for your project.

Screw Size: The length, diameter, and thread pattern of the screw must be selected based on the thickness and type of material being fastened.

Self-drilling screws are typically made from high-tensile metals, such as carbon steel, stainless steel, or alloy steel. These materials are chosen for their durability, strength, and corrosion resistance. Stainless steel is often used in outdoor applications due to its ability to resist rust and corrosion, while carbon steel offers high strength at a lower cost.

To improve their performance, self-drilling screws may be coated with various materials, including:

Zinc Coating: This is one of the most common coatings used for corrosion resistance, especially in outdoor environments.

Epoxy Coating: Provides an additional layer of protection against the elements and is often used for screws exposed to harsh weather conditions.

Ceramic Coating: Adds further durability and resistance to wear and tear, making it suitable for use in industrial applications.

Coatings help extend the lifespan of self-drilling screws by preventing rust and corrosion, ensuring they maintain their strength even in challenging environments.

Self-drilling screws are widely used in various industries and applications due to their versatility. Common uses include:

Metal Roofing: Self-drilling screws with a hex washer head are commonly used to fasten metal roofing panels. These screws create a weather-tight seal, preventing leaks and ensuring the structural integrity of the roof.

Automotive Manufacturing: These screws are ideal for fastening metal parts in automotive assembly due to their ability to drill through metal and form secure connections.

HVAC Systems: Self-drilling screws are often used in the construction of HVAC ducts and systems, where their ability to drill and fasten in one step is highly beneficial.

Woodworking: Self-drilling screws with a pan head are used in wood construction, such as decking and furniture assembly, where they provide strong, durable connections.

Masonry and Concrete: Some self-drilling screws are designed for use in masonry and concrete, requiring a pilot hole for installation.

Self-drilling screws are a staple in industries such as:

Construction: For fastening metal to metal or wood to metal, particularly in roofing and framing applications.

Manufacturing: Used in automotive, machinery, and appliance manufacturing for creating secure, vibration-resistant joints.

HVAC: For installing HVAC systems and ducts with precision and speed.

Medical: In medical applications, particularly in orthopedic surgeries, where self-drilling screws are used for bone fixation.

Self-drilling screws are highly efficient, reducing the need for a separate pre-drilled pilot hole. This eliminates extra steps in the fastening process, saving both time and labor costs. By combining drilling and fastening in one action, these screws streamline the installation process.

With their drill-shaped tips, self-drilling screws provide precise hole placement and reliable thread formation. This reduces the chances of errors during installation, ensuring a strong, secure connection every time.

Self-drilling screws are available in a wide range of sizes and types, making them suitable for a variety of materials, including metals, wood, plastic, and masonry. Their versatility allows them to be used in both light-duty and heavy-duty applications, enhancing their value in construction, manufacturing, and DIY projects.

Installing self-drilling screws is straightforward. Follow these steps:

Select the Appropriate Screw: Choose the right size and type of screw for the material and application.

Prepare the Surface: Ensure the surface is clean and free of debris that could affect the screw’s performance.

Drive the Screw: Use a power drill or screwdriver to drive the screw into the material. The screw will drill and tap the hole as it is inserted.

Check the Tightness: Ensure the screw is firmly secured, but avoid over-tightening, which could cause damage to the material or strip the threads.

Correct Speed and Force: Follow the manufacturer’s recommendations for drill speed and force to avoid screw failure.

Avoid Over-Tightening: Over-tightening can strip the threads and weaken the joint.

Proper Screw Size: Ensure the screw is the correct size for the material being fastened. Too large a screw can cause the material to split, while too small a screw can result in a weak connection.

While self-drilling screws are highly effective, they can fail if not used correctly. Common causes of failure include:

Excessive Force: Applying too much force can cause the screw to break or the threads to strip.

Incorrect Material: Using the wrong type of screw for a particular material can lead to poor performance.

Over-Tightening: Tightening the screw too much can cause damage to both the screw and the material.

Stripped Threads: If the threads become stripped, replace the screw with a new one of the correct size. Ensure the pilot hole is the correct diameter.

Screw Breakage: If the screw breaks, check that you are using the correct size and applying the appropriate amount of force.

Material Splitting: If the material splits, reduce the force applied and consider using a different screw with a washer head for better load distribution.

The main difference between self-drilling and self-tapping screws is the ability of the self-drilling screw to drill its own hole, while a self-tapping screw requires a pilot hole. Self-drilling screws are better suited for tough materials and large-scale projects where time and precision are critical.

Regular screws require a pre-drilled pilot hole, making them less efficient for applications where time is crucial. Self-drilling screws combine drilling and fastening in one step, saving time and labor costs.

Self-drilling screws are an invaluable tool in various industries, from construction to automotive manufacturing. Their ability to drill and fasten in one step saves time, increases precision, and reduces the risk of installation errors. Whether you are working on a DIY project or an industrial job, understanding the different types and best practices for using self-drilling screws will help you achieve optimal results. Always choose the right type of screw for your material and application to ensure a secure, long-lasting connection.

What is the difference between self-drilling and self-tapping screws?

Can I use self-drilling screws on wood?

How do I prevent self-drilling screws from breaking?

Are self-drilling screws waterproof?

What is the best screw size for metal roofing?

This article has covered all the essential information you need to know about self-drilling screws, including their types, materials, applications, and best practices for installation. By understanding these aspects, you can ensure that your projects are completed efficiently and with the highest level of quality.