Views: 0 Author: Site Editor Publish Time: 2025-10-23 Origin: Site

You can prevent corrosion of your heavy duty screw near the coast by choosing the right materials and protective coatings. The table below shows how material selection affects corrosion resistance:

Material Type | Corrosion Resistance Level | Application Area |

|---|---|---|

Grade 316 Stainless Steel | Highest | Marine environments, coastal areas |

Zinc Coating | Moderate | Maritime and outdoor settings |

Epoxy and ceramic coatings help block moisture and salt, giving screws extra protection. You also boost longevity by using installation methods that avoid stripping or stressing the screw. Regular inspection and cleaning keep corrosion in check.

Choose grade 316 stainless steel or silicon bronze screws for the best corrosion resistance in coastal areas.

Regularly inspect and clean screws to catch early signs of rust and extend their lifespan.

Use protective coatings like zinc or epoxy to shield screws from moisture and salt exposure.

Implement best installation practices, such as using non-conductive washers, to prevent galvanic corrosion.

Follow a maintenance routine that includes rinsing screws monthly and applying protective sprays to enhance durability.

If you work on coastal construction, you face unique challenges. Rust attacks heavy duty screws much faster in coastal areas than in dry regions. The main reason is the constant presence of moisture and salt in the air. When you use screws in high-moisture environments, you expose them to conditions that speed up rust. Moisture acts as a bridge, allowing chemical reactions to start on the metal surface. Salt, found in sea spray and coastal winds, breaks down protective layers on screws and lets rust form quickly.

Tip: Always check the environment before choosing screws for coastal structures. High humidity and salt-rich air mean you need extra protection.

Here is a quick look at the main environmental factors that make rust a big problem near the coast:

Environmental Factor | Description |

|---|---|

Moisture | Increases the rate of rust by providing a medium for chemical reactions. |

Salt | Contributes to accelerated rust, especially in coastal areas due to salt-rich air. |

Chemicals | Aggressive substances like chlorides and sulphates promote rust. |

High Humidity | Enhances the likelihood of rust by maintaining moisture levels. |

You should also know that not all screws perform the same in saltwater. For example, grade 316 stainless steel and silicon bronze resist rust very well, while hot dip galvanized screws may not last as long in these conditions.

You can spot rust early if you know what to look for. The first sign is a reddish-brown stain on the screw head or threads. Sometimes, you see pitting or small holes on the surface. If you notice the screw feels weak or the metal flakes off, rust has already started to damage it. In coastal areas, you may also see white or greenish deposits, which show that moisture and salt have attacked the metal.

Look for these signs on heavy duty screws:

Discoloration or reddish stains

Flaking or peeling metal

Pitting or small holes

Loose or weakened screws

Rust can spread quickly in high-moisture environments. If you ignore early signs, you risk the safety and strength of your coastal structures. Regular checks help you catch rust before it causes bigger problems.

When you build near the coast, you need to pick the best screws for outdoor use. Not all screws can handle the harsh mix of salt, moisture, and changing weather. If you want your project to last, you must choose corrosion-resistant screws that stand up to these tough conditions. Let’s look at the main types you can use for coastal and marine projects.

Grade 316 stainless steel is one of the best screws for outdoor use in coastal areas. You get excellent corrosion resistance because this stainless contains molybdenum. This element helps the screw resist pitting and crevice corrosion, which are common problems in saltwater environments. You can use grade 316 stainless steel for docks, piers, decks, and even structures near swimming pools. It works well with rot-resistant lumber like cedar, redwood, and tropical hardwoods. Many builders call it marine grade because it stands up to salt, chemicals, and even high temperatures. You also get better strength and durability compared to other stainless options.

Note: Grade 316 stainless steel is often called marine grade because it resists rust and corrosion in harsh coastal environments.

Marine grade fasteners are designed for the toughest coastal and marine conditions. These corrosion-resistant fasteners keep over 70% of their strength even after 500 hours in seawater. Standard fasteners lose half their grip in just 20 to 30 hours. Marine grade fasteners also work in extreme temperatures, from freezing cold to very hot days. They resist damage from cleaning chemicals and petroleum products, so you can trust them for long-term durability. If you build in areas with high salt content or pollution, marine grade fasteners are the best screws for outdoor use.

Galvanized screws are common in many outdoor projects. They have a protective zinc layer that helps slow down rust. However, in coastal and marine settings, galvanized screws do not last as long as stainless or bronze. Saltwater can break down the zinc coating, leading to rust and failure over time. You can use galvanized screws for temporary structures or where exposure to salt is low.

Silicon bronze screws are another top choice for marine and coastal projects. These screws offer excellent corrosion resistance and durability. Silicon bronze handles moisture and saltwater very well. You get high strength and long-lasting performance, making them one of the best screws for outdoor use in harsh environments. Many boat builders and dock installers prefer silicon bronze for its rust-resistant materials and ability to handle heavy loads.

Here is a quick comparison of how these materials perform in saltwater:

Material | Corrosion Resistance in Saltwater |

|---|---|

Grade 316 Stainless Steel | Excellent |

Silicon Bronze | Excellent |

Galvanized (HDG) | Moderate to Low |

You need to weigh the pros and cons before choosing screws for your coastal project. Here is a simple guide:

Grade 316 Stainless Steel

Pros: Superior corrosion resistance, high strength, works in harsh coastal and marine settings, resists pitting and cracking.

Cons: Higher cost than galvanized screws.

Marine Grade Fasteners

Pros: Keep strength in saltwater, resist chemicals, work in extreme temperatures, long-lasting durability.

Cons: Can be more expensive and sometimes harder to find.

Galvanized Screws

Pros: Lower cost, easy to find, good for less harsh outdoor use.

Cons: Moderate corrosion resistance, zinc coating can wear off, not ideal for direct saltwater contact.

Silicon Bronze Screws

Pros: Excellent corrosion resistance, high durability, strong under heavy loads, ideal for marine use.

Cons: Higher price, color may not match all woods.

Tip: For the best screws for outdoor use in coastal or marine environments, choose grade 316 stainless steel or silicon bronze. Use galvanized screws only for less exposed areas or temporary fixes.

When you select the right corrosion-resistant screws, you protect your project from rust and damage. You also save time and money on repairs. Always match the screw material to your environment and the level of exposure to salt and moisture. This way, you get the most durability and safety for your coastal construction.

You can boost corrosion protection for heavy duty screws by choosing the right coating. Zinc coatings work by forming a barrier between the metal and the environment. This barrier slows down rust, especially in salty air. In salt spray tests, zinc coatings show much better performance than uncoated screws. Cold-spray aluminum zinc coatings stand out, showing minimal weight loss and a stable corrosion rate. Hot-dip galvanizing creates a thick, durable coating that works well outdoors. Electro-galvanizing and zinc plating offer thinner layers, which suit light-duty or indoor use.

Epoxy coated screws give you another strong option. The epoxy layer acts as a shield, blocking moisture and salt from reaching the metal. You get longer-lasting screws, especially in coastal areas where humidity stays high. Epoxy coatings also help prevent scratches and chips during installation.

Ceramic and polymer coatings add another layer of protection. PTFE and Xylan are two popular choices. PTFE enhances surface corrosion resistance, while Xylan provides a tough, corrosion-resistant finish. These coatings work well in marine environments because they resist chemicals and saltwater. You can use them for projects that need extra durability and long-term corrosion protection.

Here is a quick table showing common coating types and their benefits:

Coating Type | Description |

|---|---|

PTFE | Enhances surface corrosion resistance |

Xylan | Durable, corrosion-resistant finish |

Hot-Dip Galvanizing | Thick, durable coating for outdoor use |

You get a much longer lifespan from coated screws compared to uncoated ones. In high-humidity coastal areas, coated screws last 1–3 years, while stainless steel screws can last over 10 years. Uncoated screws often fail quickly due to rust. Choosing the right coating gives your heavy duty screws the best chance at long-term protection and performance.

Tip: Always match the coating to your environment for the best corrosion protection.

When you install heavy duty screw products in coastal environments, you need to follow best practices to maximize their lifespan and performance. The right approach helps you avoid common problems like corrosion, loose deck screws, and premature failure of your decking. Let’s break down the most important steps for a successful installation.

Galvanic corrosion is a hidden threat in coastal construction. This type of corrosion happens when you use different metals together, such as stainless steel deck screws with aluminum brackets, and expose them to saltwater. The metals create an electrical current in the presence of moisture, which causes one metal to corrode faster.

Galvanic corrosion occurs when dissimilar metals touch in salty or wet conditions.

Preventing this problem increases the service life of your deck screws and other fasteners.

You can stop galvanic corrosion by using insulating materials, such as plastic washers or sleeves, between metals.

Protective coatings or sealants also help break the electrical path and keep your deck and decking secure.

Tip: Always match your deck screws and connectors to the same metal type when possible. This simple step reduces the risk of corrosion and keeps your deck strong.

Non-conductive washers play a key role in coastal deck installations. These washers act as a barrier between the heavy duty screw and the metal surface. By using plastic or rubber washers, you stop electrical contact between different metals. This method helps prevent galvanic corrosion and extends the life of your deck screws.

Place non-conductive washers under the head of each deck screw.

Use them where deck screws meet metal brackets or flashing.

Choose washers made from UV-resistant materials for outdoor decking.

Non-conductive washers are easy to install and add an extra layer of protection for your decking. They help keep your deck safe and looking good, even in harsh coastal weather.

Sealants and anti-corrosion pastes give your heavy duty screw extra defense against salt-laden air. When you apply a corrosion-inhibiting sealant, you create a barrier that blocks moisture and salt from reaching the metal. This barrier is vital for deck screws used in coastal decking, where salt spray and humidity are constant threats.

Corrosion-inhibiting sealants reduce electrochemical reactions that cause rust. Some products, like the Ford 1000 Hour Coating, protect stainless steel deck screws for over 1,000 hours in salt spray tests. Surface coatings, such as zinc lamella or galvanically applied coatings, also boost corrosion resistance for deck screws and other fasteners.

Always apply sealant or anti-corrosion paste to the threads and heads of deck screws before installation.

Use a brush or applicator to cover all exposed metal surfaces.

Reapply sealant during regular deck maintenance, especially after storms or heavy rain.

Note: The use of suitable coatings is essential for reducing corrosion damage. These coatings provide a protective layer over metallic surfaces, making them a smart choice for coastal decking.

Proper fastening techniques ensure your deck screws hold strong and resist corrosion. Start by choosing corrosion-resistant fasteners, such as grade 316 stainless steel or silicon bronze deck screws. These materials offer the best protection for coastal decks and decking.

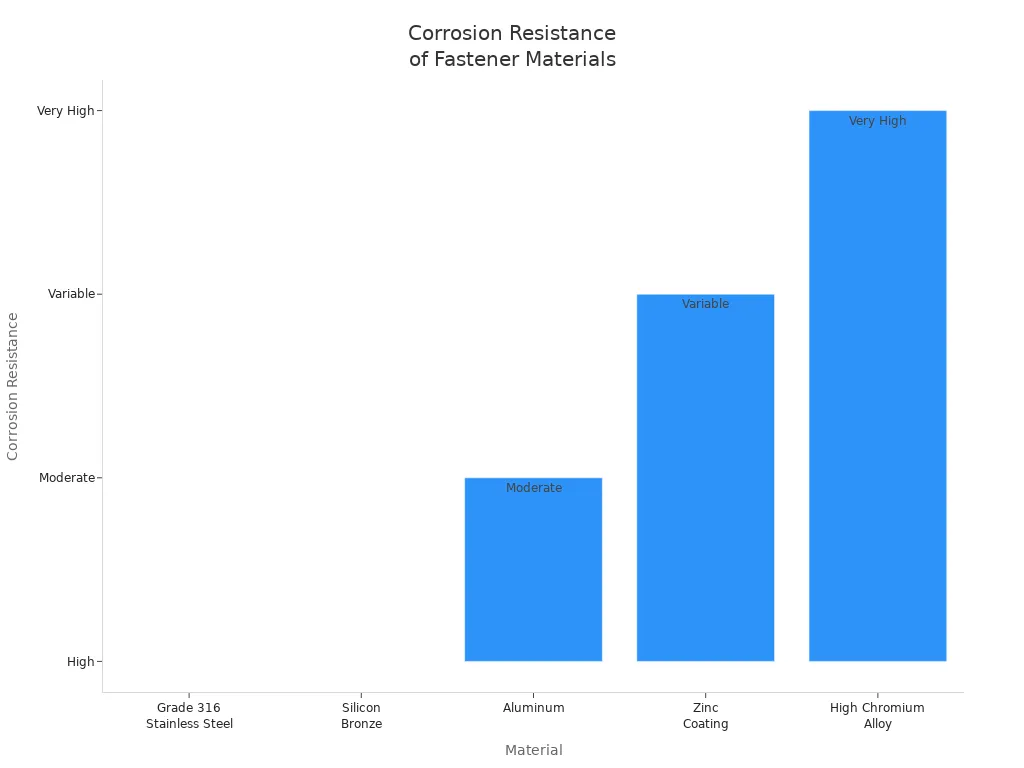

Material | Corrosion Resistance | Notes |

|---|---|---|

Grade 316 Stainless Steel | High | Best for marine use, but can corrode under continuous exposure. |

Silicon Bronze | High | Excellent for saltwater environments. |

Aluminum | Moderate | Risk of galvanic corrosion when mixed with stainless steel. |

Zinc Coating | Variable | Budget-friendly, but performance varies with environmental conditions. |

High Chromium Alloy | Very High | Opt for fasteners with high levels for best results. |

Follow these steps for secure deck screw installation:

Choose corrosion-resistant materials like stainless steel or galvanized deck screws.

Schedule regular inspections to catch signs of corrosion early.

Ensure proper ventilation under your deck to reduce moisture buildup.

Apply protective coatings or sealants to all deck screws and fasteners.

Keep your deck clean by removing debris that traps moisture.

Trim overhanging branches to prevent damage to protective coatings on your decking.

Install saltwater barriers to redirect runoff away from deck screws.

Repair damaged deck boards or flashing right away to stop water infiltration.

Callout: Secure fastening techniques help your deck and decking last longer. Always use the right tools and avoid over-tightening deck screws, which can strip threads and weaken your deck structure.

By following these best practices, you protect your heavy duty screw investment and keep your coastal deck safe for years. Proper installation, combined with regular maintenance, ensures your deck screws and decking resist corrosion and stay strong in any weather.

Keeping your marine grade screws in top condition requires regular care. You can extend their lifespan and prevent corrosion by following a few simple routines.

Salt and moisture build up quickly in coastal areas. You should rinse your screws with fresh water every month. Use a garden hose with moderate pressure to wash away salt deposits from all hardware surfaces. Focus on areas like hinge pins, roller tracks, and lock mechanisms. For best results, clean with pH-neutral cleaners and non-abrasive cloths. This method removes salt without scratching the surface.

Maintenance Routine | Description |

|---|---|

Regular rinsing | Remove salt deposits with fresh water. |

Non-abrasive cleaning | Use pH-neutral cleaners and soft cloths. |

Lubrication | Apply corrosion-resistant greases on moving parts. |

You should inspect your marine grade screws every 6–12 months. Look for discoloration, rust, or coating damage. Check for loose or deformed screws. Early detection helps you fix problems before they get worse.

Source | Recommendation |

|---|---|

Avoiding Corrosion in Coastal Installations | Schedule inspections every 6–12 months in marine environments. |

Best Practices for Military Fastener Maintenance | Inspect before and after heavy use for signs of corrosion or wear. |

Replace any damaged or corroded screws right away. Use a stable ladder for high places to stay safe. Rinse Tapcon screws every 6 months to remove salt. Inspect screws before hurricane season for rust or looseness. Reapply anti-seize lubricant each year. Watch for cracks in the concrete deck and secure outdoor items indoors before storms.

Use a stable ladder for high tracks.

Rinse screws every 6 months.

Inspect annually before hurricane season.

Reapply lubricant yearly.

Monitor for cracks or shifting.

Protective sprays and lubricants help prevent corrosion in marine applications. Products like 12|34® Lubricant & Penetrant, CorrosionX, SWEPCO 801, and 4-14 Lubricant & Penetrant form barriers against rust. These sprays disrupt corrosion on a molecular level and provide long-term protection, especially in saltwater environments.

Product Name | Key Features |

|---|---|

12|34® Lubricant | Prevents rust and corrosion, protects against electrolytic and galvanic corrosion. |

CorrosionX | Disrupts rust at the molecular level, ideal for marine use. |

SWEPCO 801 | Forms a protective barrier, extends equipment life. |

4-14 Lubricant | Offers temporary protection against corrosion in salty environments. |

Tip: Apply protective sprays after cleaning and inspection to keep your marine grade screws strong and rust-free.

By following these steps, you ensure your screws stay reliable for all your marine projects.

You can prevent corrosion in coastal areas by choosing corrosion-resistant screws like grade 316 stainless steel or marine fasteners. These options lower long-term maintenance costs and protect your heavy duty screw investment, as shown below:

Feature | Benefit |

|---|---|

Corrosion Resistance | Superior performance in coastal and marine environments |

Material Degradation Prevention | Less risk of pitting and crevice corrosion |

Maintenance Strategies | Longer life with regular care |

Regular inspection and cleaning help you spot early signs of rust. Many coastal projects, such as the Kuwait Naval Base, doubled their service life by using strong prevention plans. When you follow these steps, you extend the lifespan of every heavy duty screw, improve safety, and reduce costs.

Regular maintenance catches rust and salt deposits early.

Coastal conditions demand extra care for heavy duty screw longevity.

A good prevention plan means fewer repairs and safer structures.

You need a heavy duty screw made from grade 316 stainless steel or silicon bronze. These materials resist salt, moisture, and harsh weather. Always check for marine-grade labels before you buy.

You should inspect your heavy duty screw every 6–12 months. Look for rust, discoloration, or loose fittings. Early detection helps you prevent bigger problems.

No, regular screws rust quickly in salty, humid air. Always use a heavy duty screw with corrosion-resistant coatings or marine-grade materials for safety and durability.

Yes, coatings like zinc or epoxy can wear down. You should reapply sealants or replace screws if you see damage. This keeps your heavy duty screw strong against corrosion.

Rinse your heavy duty screw with fresh water monthly. Use a soft cloth and pH-neutral cleaner. This removes salt and prevents buildup that leads to corrosion.